Photography by Gary Chatfield and Manoon Aunpoklang

Dec. 26, 2004 will be remembered as one of the most catastrophic days in history. The Asian tsunami, which originated off Sumatra Island in Indonesia, traveled thousands of miles, destroying almost everything in its path.

|

|

In the Bangkok Post a few days after the event, an article revealed four golfers and two caddies on a navy golf course at Tublamu in the Phang-nga province of Thailand were swept to their deaths that day.

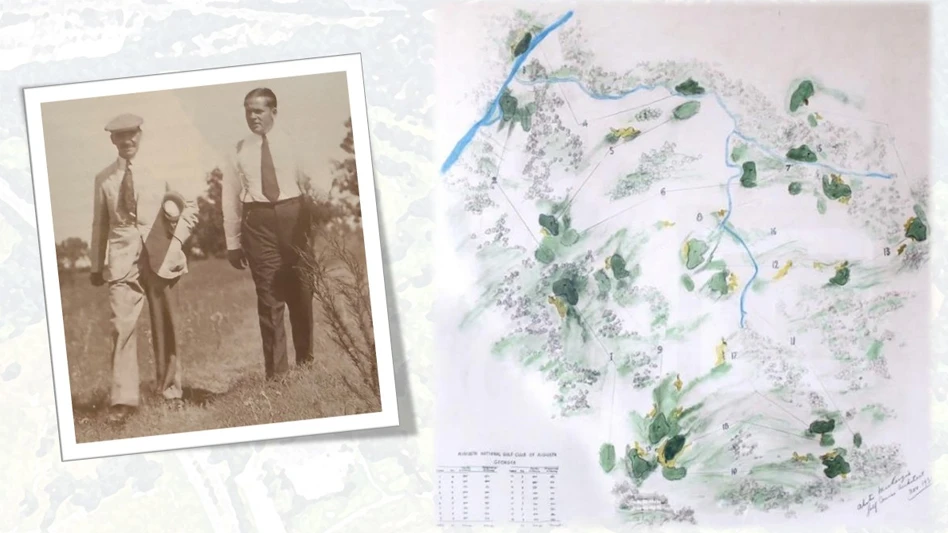

Renovation of the course started in April after the scope of work and relevant issues were sorted out. The Innotech Group, headed by Manoon Aunpoklang and assisted by Pramod Ureerug, was the project manager; Golf East’s Pirapon Namatra (pictured) was the golf course architect; Jungruk Thamdin was responsible for bulk earthwork and shaping; and Global Turf Consulting provided turf solutions and maintenance services for the turf establishment and grow-in period.

The navy’s goal was to repair the course as quickly as possible, for as cheap as possible. The $825,000 budget was for:

- Rewiring the irrigation pump motors that was submerged;

- Buying replacement equipment that was destroyed;

- Replacing bridges that weren’t repairable;

- Upgrading the irrigation system on 10 holes from a quick-coupler system to a manual-valve system;

- Repairing/rebuilding tees, fairways, bunkers and greens that were destroyed;

- Repairing the drink huts that were damaged; and

- Replacing the golf accessories that were washed away.

|

|

The pump house is about 33 feet above sea level and located about one-half mile from the ocean. The motors, which were submerged, were removed and sent to Bangkok for stripping, cleaning, rewiring and testing. Because the irrigation lake had been contaminated with seawater, most of it had already been pumped out by the time the renovation project started. While the motors were being repaired, the water treatment plant was running with the overflow water coming into the irrigation lake. A temporary diesel pump was set up to provide water for flushing and testing the system, as well as growing the surviving grass.

Because the golf course is mostly on sand and close to the sea, the natural water table is high, and water was seeping back into the lake from underground. Water samples were taken and sent away for analysis. Where stolons were planted, establishment was slow. When the test results came back, one of the worst fears was confirmed: The water salinity was 5,000 ppm.

The new equipment purchased included: four walk-behind mowers, a triplex mower for tees and surrounds, a five-gang mower for fairways and rough, a bunker machine, a tractor with a tow-behind sprayer, a three-point linkage fertilizer spreader and walk-behind spreader. Additional machinery will need to be purchased as finances allow.

|

|

Nine bridges were damaged or destroyed. Some could be repaired, and others have been completely replaced and located in more suitable locations.

Where there was quick-coupler irrigation, the main line and laterals were replaced with valves and sprinklers. Greens and tees were isolated, but the fairways were split in two halves, and the entire half of each hole could be watered at one time.

The tsunami created an opportunity to renovate the course and improve the original design. The existing grasses on the course were a mixture of zoysiagrass and Bermudagrass, with paspalum dilatatum invading in areas. About 50 percent of the grass survived and remarkably looked good three months after the tsunami with no irrigation.

Because the majority of the turf is zoysia matrella on the tees, fairways and rough, sod of the same species was trucked down from Bangkok to plant all the newly shaped areas.

|

|

Root development and establishment was twice as slow as normal because of the high salt content in the irrigation water. Planting stolons on the tees and fairways was abandoned because of the short time frame to complete all the work. Growth was slow everywhere grass was planted. Applications of gypsum were being applied every four weeks and starter fertilizers every two weeks. The greens were planted with Novotek Tifdwarf stolons to replace the zoysia tenuifolia, and it took three or four months to establish and fully cover.

Paspalum was never considered because of the high maintenance cost of it and the low budget. In Thailand, courses that have planted paspalum suffer from high fungal infections and continuous insect attacks from armyworms. Even though zoysiagrass grows more slowly, it would have overgrown the paspalum. Some paspalum stolons were tested on the seventh hole and initial establishment was just as slow as the zoysiagrass and Bermudagrass.

Around the lake and creek edges, vetiver grass was planted to stabilize the sand and provide erosion control.

Only one of the three drink huts had major damage, but that didn’t take long to fix. Almost all tee markers and flagpoles were washed away, and only a few putting cups remaining.

Heavy rains during monsoon season, which runs from May to October, hampered work at times. Small scouring and wash outs were the biggest problem.

|

|

In one way, the tsunami was a blessing in disguise because it forced improvement of the golf course, which lacked character and didn’t fully use the ocean frontage. The layout of the back nine remained the same except for the 10th hole, where the tees were moved forward and the green pushed back the same distance. This made the walk from the green on the 10th hole to the tee on the 11th 54 yards instead of 164 yards. Hole 17 was moved as close to the edge of the sea as possible, but the huge tides during the monsoon season eroded the edge of the tees and green, so they were moved inland 66 feet to avoid future problems. The routing for the front nine was turned around. New tees were built on 10 holes, and new fairway bunkers were added on 13 holes. All greens were redesigned. Pirapon Namatra from Golf East created the new design and oversaw the earthwork.

The work force for fine shaping, fertilizing, grassing, watering and topdressing consisted of the unemployed caddies and outside labor. Volunteer golf course superintendent, Sub-Lieutenant Watcharapong Taengin, who has worked on the course since its inception, and his assistant, Kumpol Gatsattabun, ensured a tight schedule was adhered to. They assisted construction superintendent Narong Jindapolu, whose 10 years in the region proved invaluable. Grassing was completed by early October. The deadline for the grow-in period was the beginning of December, so the course would be ready for play by the 26th, which it was.

Additionally, the salt-sensitive trees were affected badly. Hundreds of salt sensitive trees have died and will need to be removed, but others sprouted new growth. When the dead ones removed, a more links feel will be created.

In time, all the scars will heal and that fateful day in late 2004 will just be distant memory. GCN

Gary Chatfield is managing director of Global Turf Consulting (www.globalturfconsult.com) and has resided in Asia the past 14 years.

Latest from Golf Course Industry

- Tartan Talks 116: Doug Smith

- Audubon International adds 127 golf courses to Monarchs in the Rough

- USGA’s GAP preps for fourth year

- Protect your vehicles from rodent damage

- VIDEO: Fun with fairways

- From the publisher’s pen: Humble giving

- Syngenta adds two to western U.S. team

- The Aquatrols Company introduces soil surfactant for Canada