SubAir is subsurface moisture removal and aeration technology that works by promoting healthier and stronger playing surfaces through moisture content management, subsurface aeration and root-zone temperature control.

The SubAir concept was invented by Marsh Benson, director of golf at Augusta National Golf Club. Benson was looking for a way to maintain healthier turf in the hot, humid southern climate. He decided the system he was developing would benefit other superintendents. Since the SubAir System was formed more than 10 years ago, the system has evolved. Currently, it’s being built at a production facility in Graniteville, S.C.

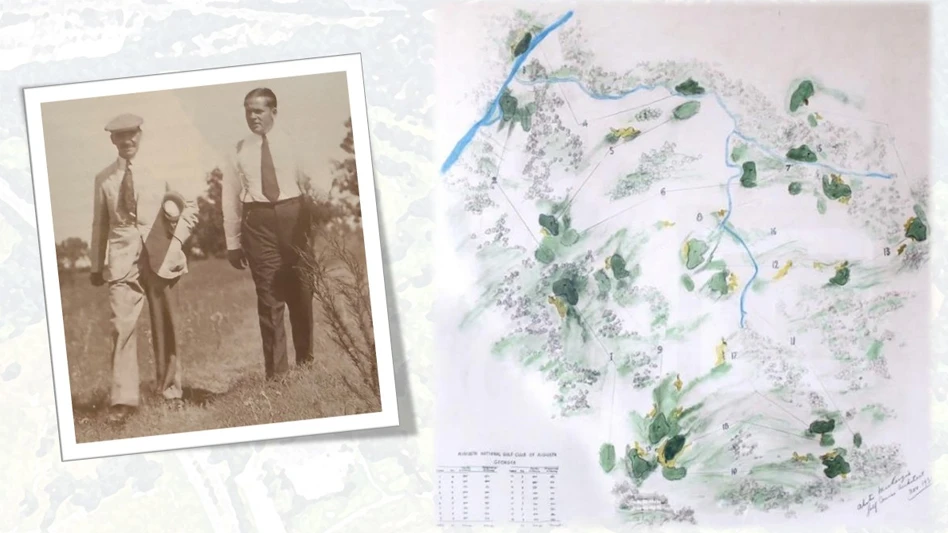

Each system is connected to the existing subsoil drainage pipe network of a golf green or sports field and is engineered to operate as a vacuum or aerator (See diagram below). As a vacuum, SubAir increases the rate water is moved from the surface through the soil profile. As an aerator, SubAir forces air from the subsoil pipes through the soil profile to provide needed oxygen. By removing moisture and providing air, the system also provides relief from extreme temperatures.

Although the system is best known for the way it rapidly removes excess water from golf greens, its long-term benefits for golf courses come from the air exchange it provides the turf.

“Grass is like a person, it requires fresh air,” says Kevin Crowe, agronomist and director of golf projects for SubAir. “Instead of disturbing the surface with a mechanical aerator, our system forces fresh air through the soil profile.”

Installation of SubAir can be done in one or two days per green, causing little disruption to play at an existing course. A SubAir vault, housing the blower that provides a vacuum and pressure mode, is connected to the existing piping network of the golf green. The vault is installed at the highest elevation forcing the air to flow uphill to the SubAir unit and allowing gravity to drain water down to the outfall.

An assembly called a distributed separator connects the vault to the green’s drainage network and acts to separate the air from the water. The assembly separates the air and the water, moving the airflow to the SubAir vault and sending the water toward the outfall.

A dual valve is used on the end of each outfall to create an air lock to force the air through the soil profile so it doesn’t escape through an open-ended pipe. Controls for the units are housed in a standard irrigation enclosure, which is located away from the green.

Once the installation is complete, only the air intake/exhaust and vault inspection port are visible above the surface. Installation of a SubAir system costs $20,000 to $25,000 per unit.

For more information about SubAir, visit www.subairsystems.com.

Elese Cegelis customer and marketing services manager for SubAir.

|

|

Latest from Golf Course Industry

- Tartan Talks 116: Doug Smith

- Audubon International adds 127 golf courses to Monarchs in the Rough

- USGA’s GAP preps for fourth year

- Protect your vehicles from rodent damage

- VIDEO: Fun with fairways

- From the publisher’s pen: Humble giving

- Syngenta adds two to western U.S. team

- The Aquatrols Company introduces soil surfactant for Canada