John Deere

John Deere introduced two new electric utility rakes at the 2026 GCSAA Conference and Trade Show: the TruFinish 1235 Electric Utility Rake and TruFinish 1210 Utility Rake. The TruFinish 1235 Electric Utility Rake is the first electric utility rake model available within the John Deere portfolio.

“Our equipment is trusted to perform on some of the world’s most renowned golf courses,” said Kim Ehasz, global manager, market development and strategy, John Deere. “Our operator-first solutions, including the new TruFinish 1235 Electric Utility Rake, are designed to elevate efficiency year-round while helping customers achieve their sustainability and performance goals.”

The TruFinish 1235 Electric Utility Rake delivers quiet, zero-emissions performance. Powered by dual lithium-ion batteries, the TruFinish 1235 Electric model is ideal for golf courses, sports fields and municipalities with noise or emissions restrictions.

Featuring a new TechControl display, operators can customize transport and raking speeds, cruise control, differential lock and rear rake operations, helping superintendents achieve consistent results. Using a 700W charger, the TruFinish 1235 Electric Utility Rake can be fully recharged overnight.

The TruFinish 1210 Utility Rake replaces the 1200A Bunker Rake and boasts a variety of updated styling and design improvements, including a newly increased ground clearance. Boosting overall comfort and efficiency, operators can benefit from the new, adjustable seat, added personal storage and dedicated hand tool holders for quick access on the go.

Integrated JDLink connectivity on the full utility rake lineup provides machine location, operating hours and performance data insights to support proactive fleet management, helping to increase overall uptime and productivity.

John Deere also showcased its 2026 PrecisionCut, E-Cut Hybrid and E-Cut Electric Walk Greens Mowers, along with the newly updated GPS PrecisionSprayers for the ProGator 2020A and 2030A models in Orlando.

Focusing on user experience and cut quality enhancement, the full portfolio of John Deere Walk Greens Mowers have been refined for 2026, including all PrecisionCut, E-Cut Hybrid and E-Cut Electric Walk Greens Mower models. With new design and ergonomic improvements, simplified adjustments and boosted cut consistency, the MY2026 Walk Greens Mowers offer thoughtful enhancements for the golf market.

All walk greens mower models now include a clutch control integrated into the operator presence bail, streamlining machine operations while improving operator control. The newly designed donut-style handlebar isolators help self-center the handlebars, keeping the cutting unit engaged for a more consistent cut on the course. All walk greens mowers now feature a modernized side cover styling, which delivers a refreshed appearance for 2026.

On the SL Walk Greens Mower models, John Deere introduced an updated bedknife-to-reel adjustment system, which features a thirteen-millimeter hex shaft design for more consistent adjustments and simplified tool requirements when checking bedknife-to-reel clearance.

Featuring an improved throttle control positioning, the lever on the 185 and 225 E-Cut Electric Walk Greens Mowers now optimizes the operator’s range of motion, increasing overall ease of use. The strategic design enhancements help reduce the effort needed to adjust traction speed, helping operators work more comfortably and efficiently.

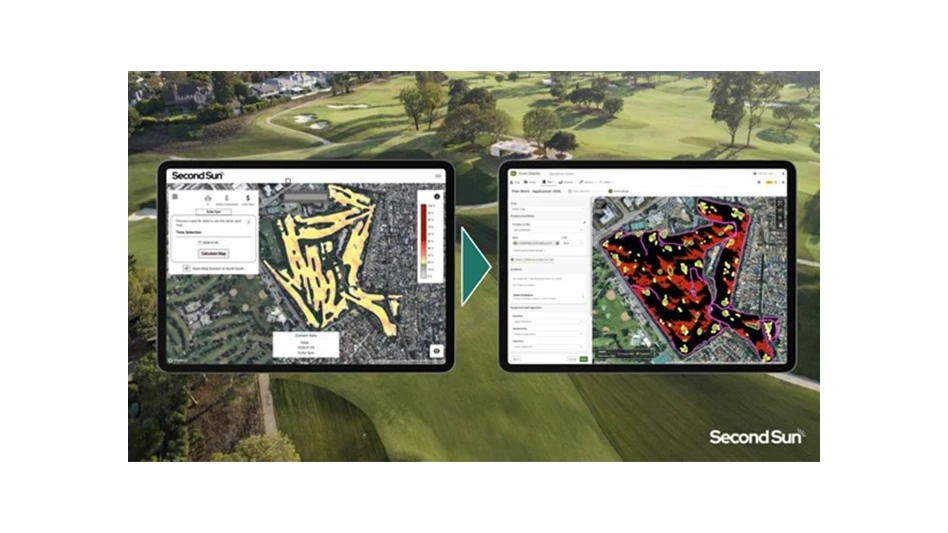

The 2026 ProGator 2020A and 2030A GPS PrecisionSprayers received technological upgrades and design enhancements to help improve connectivity and reliability. Now featuring a StarFire 7500 Receiver with an optional SF-RTK correction signal, the models offer up to 1 inch of horizontal accuracy without the need for additional hardware for adjustments. In addition, a strategic transition to JDLink M Modems provides the same level of connectivity and reliability on the course without needing an external antenna. Future models will include an improved boom harness-to-valve connector that increases the durability and reliability of spray system operation.