The Turning Stone Resort & Casino, owned by the Oneida Indian Nation, started out as a bingo hall in 1979. Now it includes five public-access golf courses, all built within the past 10 years, and a wide range of activities and entertainment. With more than 1,000 acres devoted to golf and 5,000 employees, Turning Stone faces a variety of turf challenges daily.

Matt Falvo, the superintendent of the Atunyote Golf Club, knows all about those challenges. With 18 holes set amid vast, open spaces and rolling hills, the Tom Fazio design has a park-like feel, forgiving fairways, steep-faced bunkers and plenty of bluegrass rough.

Falvo is preparing to host the second edition of the PGA Tour Turning Stone Resort Championship Sept. 29 – Oct. 5. In 2007, Atunyote hosted its inaugural PGA event after a difficult year, during which dollar spot and brown patch were recurring problems.

“Those two diseases were a big problem for us,” Falvo says. “We had the PGA event looming in late 2007, and we were determined to get the course ready for the kind of national attention the PGA entails. To that point, we were tank mixing our own fungicides to manage the diseases we were getting.”

While results were satisfactory, Falvo wanted to make sure the course had the kind of good looks required for a televised event. He turned to Scott Waltz, a Bayer Environmental Science sales rep, for advice. Waltz introduced Falvo to Tartan, a broad-spectrum fungicide that provides preventive and curative control on greens, tees, fairways and roughs.

Leading up to the PGA event, Falvo was interested in StressGard technology, which is included in Tartan. Products containing StressGard help the turf plant manage the stresses of golf course conditions more effectively, allowing the development of greater root mass and topgrowth under heat stress. Additionally, Tartan effectively controls 13 turf diseases, including dollar spot and brown patch.

Falvo shared the information with his colleague, Eric Strzepek, superintendent for two other Turning Stone courses: Shenendoah, a Rick Smith design, and Kaluhyat, a Robert Trent Jones Jr., design. Waltz even brought both superintendents to the Bayer Development and Training Center in Clayton, N.C., for a first-hand demonstration of how StressGard technology works. Impressed with the results, Turning Stone ordered more than 40 cases of Tartan for the three courses managed by Falvo and Strzepek.

While there are major differences in design and layout among the three courses, the turf varieties are essentially the same. All putting surfaces at Turning Stone are A-4 bentgrass; the fairways are a mixture of Pennlinks and Penneagle bentgrasses (except for Atunyote, which is Pennlinks only); and the roughs are a blend of bluegrass and fescue.

“I applied Tartan at Atunyote in July 2007 and again 10 days before the PGA tournament, at the rate of an ounce-and-a-half per 1,000 square foot,” Falvo says. “Honestly, the greens looked spectacular on TV. The PGA tour players were almost blown away by how the course looked. Even the announcers on the Golf Channel were calling us the ‘Augusta of the North’. It was a big deal.”

Corporate use, heavy use

The two courses Strzepek manages might not be on TV, but they endure considerably more play than Atunyote. While Falvo’s course averages about 6,000 rounds a year, Shenendoah and Kaluhyat host more than 30,000 rounds a year between them.

Because Turning Stone is only 30 minutes from the business parks of Syracuse, about 60 percent of the rounds on Shenendoah and Kaluhyat come from corporate outings.

“We pull from Syracuse, Rochester and even New York City, and the consistently heavy use means we have to struggle a bit with maintenance,” Strzepek says.

The two courses he manages are very different. Shenendoah is a lengthy course and very open with a plethors of native, unmanaged grasses, mostly fescue and bluegrass. Kaluhyat, on the other hand, is a tight and narrow course with little room for player error. Both courses are Audubon International Certified Signature Sanctuaries.

“Last year was a heavy year for disease, but on my courses, I witnessed the long control period Tartan provided, especially over dollar spot,” he says. “I got upwards of 45 days control on Shenendoah. On Kaluhyat, I got about 35 days.”

Effluent water challenges

Besides diseases, weather is another issue at Turning Stone. Summers can be cool, or hot and sticky, or just rainy. Weather affects herbicide and insecticide use, mowing, the need for aeration and other cultivation practices.

Water is a topic that gets Falvo’s and Strzepek’s attention.

“Water is an ongoing challenge at Turning Stone, on all the courses,” Falvo says. “We have 1.2 million gallons of effluent water flowing onto the property every day. Quantity isn’t an issue for us, quality is.”

On Shenendoah and Kaluhyat, Strzepek helps promote root growth and good drainage by core aerifying twice each year, pulling cores in May and October. Greens are mowed daily down to 1/10-inch, fairways are mowed three times a week, and roughs once a week.

Falvo’s regimen is similar to Strzepek’s, with one exception: Because his course includes more than 100 acres of rough, it takes four guys on the grounds crew mowing the rough every day to keep up.

Turning Stone’s courses have quickly gone from new to known nationally. Judging by the dedication of its superintendents and their willingness to assimilate the latest turf practices and products, it’s easy to see the roots of their success.

Managing anthracnose

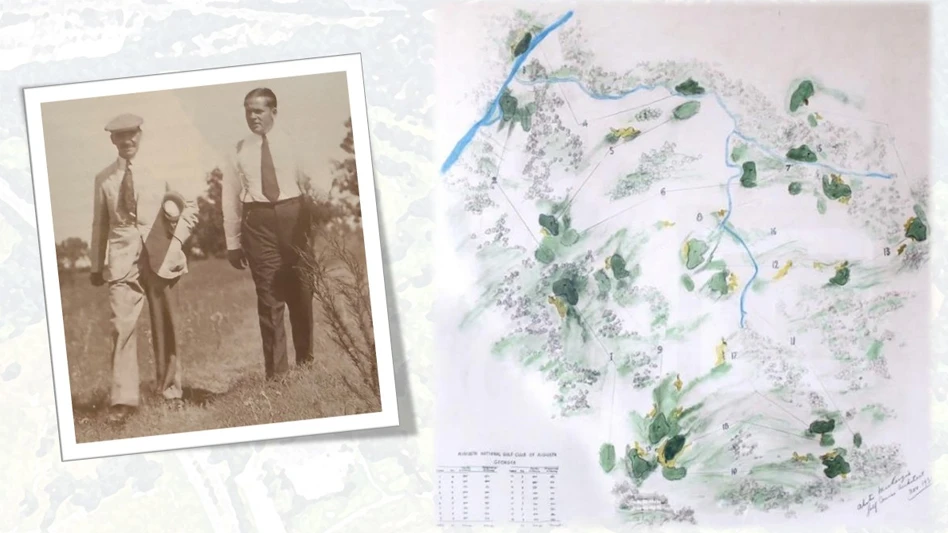

The Pittsburgh Field Club in Fox Chapel, Pa., might well be one of the areas best-kept golf course secrets. Designed in 1882 by Alexander H. Findlay, known as the father of American golf, the 130-acre course is coveted by its 800 members. The active membership racks up about 25,000 rounds each year.

One of superintendent Mike Zedreck’s biggest maintenance challenges – aside from the high level of play – is anthracnose.

“Although we get a little dollar spot on the fairways and tees now and then, our No. 1 problem is anthracnose, and almost everything is oriented around managing it.”

In 2006, Zedreck first learned about Tartan fungicide from Bayer. He tried the product in 2007 on the Poa annua greens, and the mixed Poa annua and bentgrass tees and fairways.

“It worked very well, and the StressGard technology helped from an aesthetic perspective too. The turf was noticeably healthier and greener.”

Although Zedreck is clearly a new fan of Tartan, he is adamant about controlling stress on the turf grass from a holistic standpoint.

“We are careful about how much stress we put on the grass in terms of aerification, grooming, rolling and mowing,” he says. “We scrutinize the fertility levels and the micronutrient results of our soil tests. You can’t deal with anthracnose just with chemicals. You have to focus on nutrient levels. You’ll never completely get rid of it, but you can keep it at low levels.”

Latest from Golf Course Industry

- Tartan Talks 116: Doug Smith

- Audubon International adds 127 golf courses to Monarchs in the Rough

- USGA’s GAP preps for fourth year

- Protect your vehicles from rodent damage

- VIDEO: Fun with fairways

- From the publisher’s pen: Humble giving

- Syngenta adds two to western U.S. team

- The Aquatrols Company introduces soil surfactant for Canada