A club doesn’t last 125 years without gazing ahead. At Wichita Country Club, the oldest private club in central Kansas, morning fairway maintenance routines will look different in 2026.

A revered Heartland golf stalwart, Wichita Country Club recently received the most sophisticated golf course maintenance tools in its history: two Greensmaster eTriFlex 3360 with GeoLink Mow units. The arrival of the Toro autonomous fairway mowers at facilities like Wichita Country Club coincides with a perplexing yet prosperous moment in the golf market. Everybody seems to be playing more golf and expecting better golf despite a dwindling pool of job candidates seeking to spend days, weeks, months and years maintaining golf courses.

Forward thinking is part of the Wichita Country Club ethos. The club grew large enough to move twice in the first half of the 20th century. The membership unveiled a Bill Diddel-designed course on Wichita’s east side in 1950. The layout matured nicely, and the club continues to prosper on the gently rolling site.

Observe. Study. Shift proactively. Implement.

“Wichita Country Club has a commitment to excellence and innovation that has put us at the top of the field for over a century now,” superintendent Curtis Schriever says.

Courses in the Heartland and beyond will undoubtedly follow Wichita Country Club into autonomous fairway mowing. But before adoption comes thorough exploration.

Schriever, a native of Partridge, Kansas, a small south central Kansas agrarian community, landed one of the Midwest’s most desirable turf jobs when Wichita Country Club hired him in 2022. The club was ahead of industry times, investing in major course renovations guided by architect Tripp Davis and efficiency-boosting maintenance tools such as GPS-guided sprayers by the time Schriever arrived.

A renovated course, with Meyer zoysiagrass fairways expanded from 25 to 35 acres, heightened expectations as golfers used the club more due to remote work and other lifestyle changes. Plus, finding quality labor in Wichita, a city with a brawny manufacturing sector, was becoming trickier. “The demands of golf have changed, especially post-renovation,” Schriever says. “It’s kind of unspoken that maintenance levels need to increase.”

The labor crunch was one of four converging factors that sparked Schriever’s interest in autonomous mowing. “We can’t create people outside of these walls to come fill these positions,” he says. Equipment approaching the end of its peak life cycle, Toro’s willingness to work with the club on a future maintenance model and the presence of talented equipment manager Trevor Campbell further nudged the club toward an autonomous future.

A Kansas State University graduate who developed his turfgrass skills at multiple East Coast private clubs before returning to his Midwest origins, Schriever contacted venerable and emerging equipment manufacturers to arrange autonomous mower demos at Wichita Country Club. Big or small units, rough or fairway height, wide or narrow stripes, rotary or reel, it didn’t matter. Schriever wanted to examine how nearly every available and looming autonomous solution performed on the parkland-style layout. “We’ve made as many requests as we could to get every piece of technology in here so that we can make the best decisions,” he says.

Schriever and the club waded deeper into the exploratory process in 2025 and leaned into its solid relationship with Toro distributor Professional Turf Products. Schriever worked collaboratively with PTP’s Brad Gray and Derek Harrison and Toro district sales managers Guy Oyler to determine the feasibility of using the Greensmaster eTriFlex 3360 with GeoLink Mow on Wichita Country Club’s fairways. Factors assessed ranged from cell signal coverage and proximity to a RTK station to the width of the six bridges crossing a creek intersecting the property. Toro placed sensors on existing fairway mowers to measure signal strength throughout the course.

“It was huge for me to know before we even got official quotes that our site was exceptional for this technology,” Schriever says. “If we had a mediocre site with mediocre GPS and satellite quality, we probably wouldn’t be going this route.”

Oyler, who lives in Kansas City and collaborates with Toro distributors and superintendents west of the Mississippi River, has coordinated a dozen autonomous fairway mowing demos this year for distributors and superintendents. Wichita was one of his 2025 stops. The demos and subsequent conversations reveal contrasting and nuanced reasons for the impetus behind autonomous fairway mowing exploration. “It’s interesting to learn how there’s a different fit for everybody,” Oyler says. “You show up to a place thinking this is how you’re going to pitch it. But it’s about listening and finding the best solution for the customer.”

Schriever emphasizes Wichita Country Club’s implementation of autonomous fairway mowing isn’t about replacing labor. “The way I see it is that we can keep the same staff and just relieve some of the burden of mowing,” he says. “Mowing is a job where every time you do it, you know you’re going to have to do it again. It’s one of those jobs you’re never gaining ground on.”

The club employs around 25 golf course maintenance employees during the busy golf and active Transition Zone growing season, with fairway mowing occurring three or four days per week. A typical fairway mow begins at 6 a.m., ends at 1 p.m. and requires four employees.

“We can now reallocate those hours to something else,” Schriever adds. “I think about how much more we can accomplish and how much more detailed we can be with our water applications, our bunker maintenance, our edging. All the little things that make a really exceptional experience we’re going to be able to do by trading out those labor hours.”

Little things separate good from great in the modern golf market. Oyler, a former golf course superintendent, hears turf pros and stakeholders cite straighter mowing lines, more dynamic striping and even tidier cleanup passes as attractive tangible benefits of autonomous fairway mowing to complement the intangible efficiency gains and labor reallocation.

“Everywhere you go somebody has a different thought about the way it’s going to be best utilized on their property, which has been shocking to me,” he says. “I thought it would be everybody goes out and buys a few of them to replace their units and then moves on.”

Supporting the befuddling quest for elevated conditions requires a deep understanding of technology’s potential. Helping superintendents and clubs determine autonomous fairway capabilities requires different mindsets. Toro responded to evolving needs by creating an advanced technology field support team to bolster its Greensmaster eTriFlex 3360 with GeoLink Mow and other autonomous solutions, including the Turf Pro and Range Pro series. Toro distributors are adding specialized positions to oversee efforts involving autonomous equipment.

“As this technology is changing and growing, we need to change and grow,” Oyler says. “Part of that is hiring somebody in that role, which is interesting because it’s not your typical salesperson. It’s now somebody technology driven in that role.”

Wichita Country Club is among the first clubs to purchase the Greensmaster eTriFlex 3360 with GeoLink Mow. The units arrived in mid-October, and Schriever’s team is using the end of 2025 to map fairways and gradually integrate autonomous fairway mowing into its operation. Constant 2025 dialogue with PTP and Toro, plus nearly a decade of GPS spraying experience at the club, yielded instant comfort and anticipation about 2026 possibilities.

Assistant superintendents Perry Schmiedeler, Eric McKinsey and Hunter Hill rotate leading daily maintenance efforts, with each one holding the role for a one-week period. Crew leaders, Schriever says, will manage autonomous fairway mowers like they would employees. Schriever and his assistants have discussed having the weekly crew leader arriving earlier than other managers to dispatch the autonomous fairway mowers, increasing the gap between maintenance and play. They are also considering mowing fairways at night when irrigation doesn’t need to be run.

“There are a lot of different scenarios,” Schriever says. “From the playbook we have talked about, the options are pretty much limitless.”

Since PTP delivered the Greensmaster eTriFlex 3360 with GeoLink Mow units to Wichita Country Club, Schriever has become a popular figure in his text message chains with industry friends and peers. Visitors wanting to learn more about the mowers are frequent; questions being fielded by Schriever are abundant.

“I don’t think there’s a way we’re not all doing this in the next 10 years,” he says. “In some form of fashion, we all will be trying to automate.”

Establishing and thoughtfully tweaking proven routines amid societal and technological changes will always keep places like Wichita Country Club revered and relevant.

“People like cool stuff,” Schriever says, “and this makes people excited knowing that we’re doing something on the cutting edge.”

Part 1: Preparation

Part 2: Execution

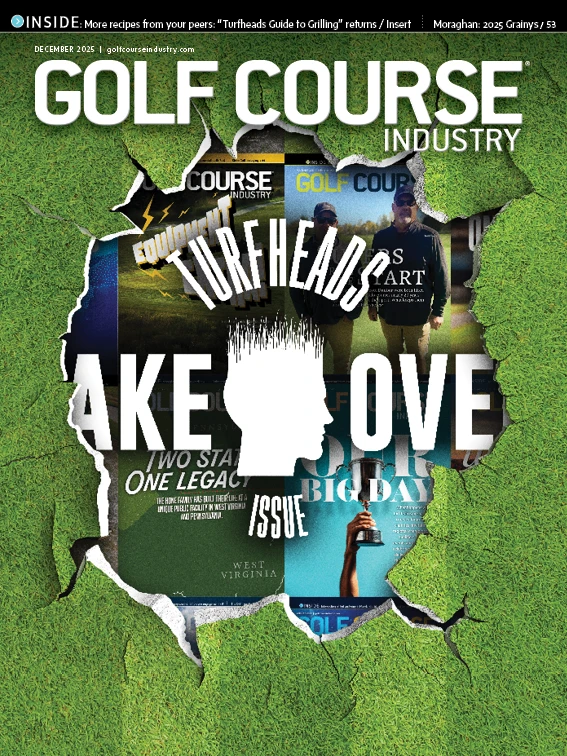

Explore the December 2025 Issue

Check out more from this issue and find your next story to read.